How Safety Impacts Profits

Author

Adam Cooper

Time to Read

3 minutes

How big does a construction company have to grow before it needs a safety program? Is it determined by sales volume, number of employees or contract sizes? In truth, it is never too early to establish written safety policies and procedures and enforce them. Just a few simple policies can have an enormous impact on the workers’ safety and health. To develop a more comprehensive program, standardized safety programs can be purchased online for a few hundred dollars and then customized to the company’s specific requirements. And many insurance companies will provide these for free to their clients.

Some business owners feel there’s little benefit to establishing and enforcing a safety program, arguing their company doesn’t have many employees or only performs small projects. But business owners who have had to deal with a lost-time accident or workers’ compensation claim know it’s worth the effort.

safety program, arguing their company doesn’t have many employees or only performs small projects. But business owners who have had to deal with a lost-time accident or workers’ compensation claim know it’s worth the effort.

Workers’ compensation claims are often settled for hundreds of thousands (or even millions) of dollars, which can be devastating to a small business. Even if the company can survive the financial impacts, the claim can have long-term effects on its insurability and ability to pursue work.

Recordable accidents (an injury or illness under OSHA that requires medical treatment beyond first aid, as well as one that causes death, days away from work, restricted work or transfer to another job, or loss of consciousness) affect a company’s Experience Modification Rate (EMR), which insurance companies use to gauge both past cost of injuries and future chances of risk. The higher the EMR, the higher workers’ compensation insurance premiums will be.

Owners and general contractors also use a contractor’s EMR as an influencing or determining factor when awarding projects and contracts. Subcontractors with high EMR ratings are often disqualified from bid opportunities. Contractors that lack formal safety programs also may find that they do not qualify to bid on certain projects. For many general contractors, safety is just as important as pricing, and they simply will not work with anyone who puts workers at risk.

And don’t forget that OSHA is continually visiting construction sites “to assure safe and healthful working conditions for working men and women by setting and enforcing standards.” As of Jan. 2, 2018, the base fine for a violation is $12,934, and failure to correct the condition results in an additional $12,934 per day. Most small contractors cannot absorb these types of unplanned costs without significant impact to the company’s bottom line. Establishing and implementing a safety program often costs less than just one OSHA fine.

Employees First

The most important reason to implement a safety program is the health and well-being of employees. They are the lifeblood of the company; they install the materials, perform the work and truly allow the company to exist. They are a firm’s greatest resource. No one would want to willfully injure or kill an employee, but failing to establish and enforce basic safety practices is putting them all at increased risk. Even the most basic safety practices, such as a 100 percent glove policy, can prevent serious injuries and help ensure that everyone goes home in the same condition as they arrived each day. A more comprehensive safety program further reduces the risks, helping to keep the workforce healthy and productive.

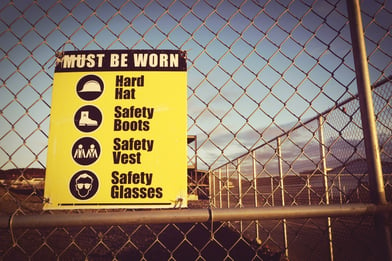

Compliance is the key to a successful program. This includes ongoing training, often in the form of weekly toolbox talks, in conjunction with the correct personal protective equipment. job hazard analysis or pre-task planning exercises are often utilized to continue to keep safety at the forefront of the workers’ minds as they perform their duties. The act of identifying and removing risks and hazards before starting any work is crucial to preventing accidents and injuries.

Compliance is the key to a successful program. This includes ongoing training, often in the form of weekly toolbox talks, in conjunction with the correct personal protective equipment. job hazard analysis or pre-task planning exercises are often utilized to continue to keep safety at the forefront of the workers’ minds as they perform their duties. The act of identifying and removing risks and hazards before starting any work is crucial to preventing accidents and injuries.

Workers may initially resist adopting safety protocols and practices, citing that they don’t need additional protection, or that it’s slowing them down from completing their work. But when employees truly understand and believe that the company is looking out for their wellbeing, it naturally provides them with a sense of being appreciated and valued, resulting in a more productive workforce and reducing attrition rates. It’s always more cost-effective to retain good employees than to find, hire and train new ones, so protecting and retaining the workforce always makes good financial sense.

Establishing safe practices and implementing a formal safety program typically results in a lower EMR, which in turn reduces the cost of workers’ compensation insurance, thereby saving money from payroll expenses. It also reduces exposure to lawsuits and the risk of workers’ compensation claims that can potentially bankrupt a small business.

It has been proven time and again that a written safety program that is adopted and enforced results in fewer accidents and safety incidents, and results in a more productive workforce. As the construction market continues to become more competitive, with reduced project timelines and increased production demands, the opportunities to take shortcuts become more appealing.

Take care that discounting safety is not an option. In the long term, the risks never outweigh the rewards.

If you're ready to start working on your business, let's talk!

Ascent Consulting’s mission is to Build Better Construction Companies.

We are committed to delivering impressive results in the areas of

profitability, performance and growth.

Tagged with:

2 Responses