In this article, we are going to explore project labor – the part of every project with the most risk and the least control.

Labor cost management is typically what defines a project as a success or a failure. Budgeting, forecasting, and managing the other costs on a project (materials, subcontracts and general conditions) is fairly straightforward, but labor is usually what makes or breaks a job.

(As published in EC&M Magazine, February 2015)

A good superintendent and a productive workforce typically lead to project success, while poor or insufficient supervision, coupled with an under-producing workforce is a recipe for financial disaster.

Let’s begin by examining the evolution of labor management in a growing contracting business. A small contractor will typically start out with the owner acting as both project manager and superintendent – they’re in the field running the crew, often wearing tools themselves, performing one project at a time. As they meet with some success and begin to grow, they hire or promote employees to foreman or superintendent roles so the company can perform two or more concurrent projects. These supervisors will have varying management abilities and styles, and see varying levels of success depending on experience, project type, workforce personnel, general contractor, job-site conditions, location, schedule, etc.

Owners will typically stay fairly involved in job-site operations to support these supervisors and help ensure project success. They may also install project managers between themselves and the field to delegate responsibility as the company grows. As contractors continue to grow, more supervisors and project managers are added to manage the increased project load. This is when contractors typically start to see labor cost overruns on projects.

Once a project crew reaches 5-10 workers, it becomes critical to start tracking labor. The average ten-worker crew can carry a weekly cost of $10,000 with a burden. It’s simple math: The longer the crew is on the job, the more it costs. If you fail to plan your work, the more likely you will extend your presence on the job site and exceed your labor budget.

Now, let’s look at how we can start to manage our workforce from a budgetary standpoint. This begins by setting a labor budget, either from the estimate or construction takeoff. If the project was estimated with a standard software package, the estimate summary should provide labor hours for each type of work to be performed and the extended costs based on the estimated labor rate. If the work was estimated using unit pricing (material and labor combined), then material costs must be determined first, then deducted from the unit pricing to determine the overall labor budget. Once you have a labor budget value, simply divide by the average wage rate on the project and you will have the total number of hours for the project. Let’s create a sample project to work with:

Sample Project:

Unit pricing from the estimate (materials and labor) = $50,000.

Material costs from vendor quote = $17,000

Labor budget = (Unit pricing – Materials) = $33,000

Average burdened labor rate = $22/hour

Labor hours = $33,000/$22 = 1500 hours

Check our article on Construction Business Development & Sales Incentive Plans

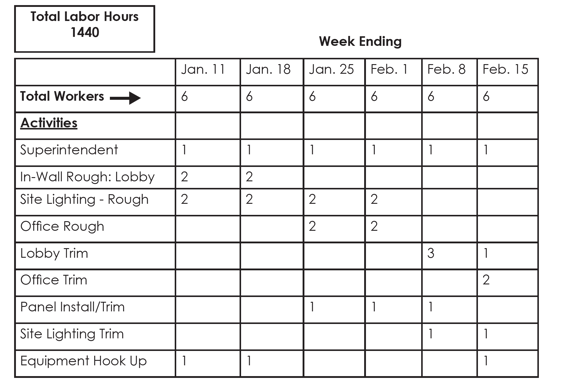

Now that we have the total number of hours on the project, we can build a man-loading schedule. This can be a simple spreadsheet that lets you allocate manpower by the day or week. Note that the man-loading schedule you create should correspond to the overall project schedule supplied by the general contractor. Here’s a six-week man-loaded project schedule for our sample project:

This man-loading schedule is a valuable tool. It provides a roadmap for the superintendent, to determine how many workers should be assigned to each activity each week. It also organizes the workforce and allocates the budget hours across the life of the project, helping to ensure that the labor budget isn’t exceeded (we’ve forecasted 1440 hours against our budget of 1500 hours). It also provides a way to check the progress of the project and identify labor issues. For example, if the panels are scheduled to be complete by 2/8, and on 2/1 they’re not close to complete, you know you’ve got a problem.

This may be all a contractor needs to effectively manage smaller projects. However, as contractors continue to grow and take on bigger projects, more tools and controls become necessary to effectively manage project labor. The next step is to begin to manage labor through Productivity.

The articles below are great additions to the above information:

Productivity

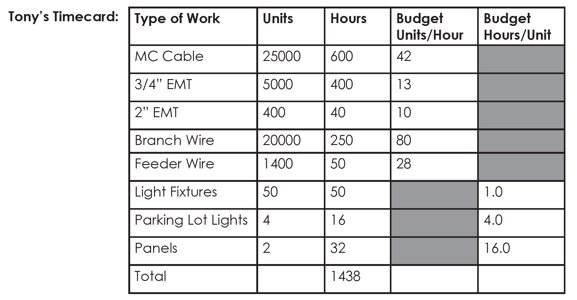

Productivity is simply a measure of how much material is installed in a given amount of time. Electrical contractors typically measure material in feet (conduit, cable, wire) or in a quantity of units (fixtures, panels, device trim, pieces of equipment). If the project is estimated with a software package, then these quantities may be provided in the estimate. If not, then a takeoff will need to be performed by the project manager and/or superintendent. Let’s continue our example and say that the project manager only received unit pricing, so he did a takeoff to determine the quantities of materials he’s going to track for productivity. He also separated out the estimated hours for each type of activity, and loaded all the info into a spreadsheet:

The two right columns now show the calculated productivity rates for each type of activity. For materials measured in feet (top 5 rows), we will use a ‘units per hour’ rate. For materials measured in quantities or counts (bottom 3 rows), we use the ‘hours per unit’ rate. These are now our production goals for the project. In simple terms “Meet these goals and the labor will come in on budget. Fail to meet these goals, and labor costs will overrun the budget”. Although there are other factors that can have an impact on project labor costs, productivity is by far the most significant factor in project success. Measuring productivity rates is the most successful indicator of labor success and failure.

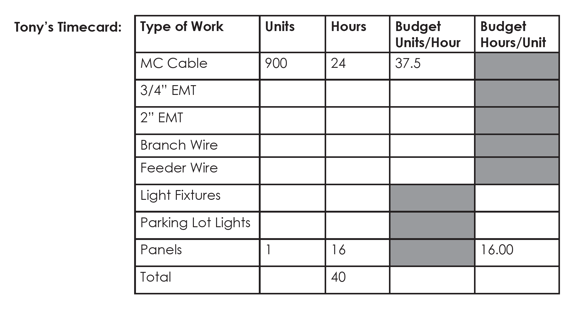

So, how do we take these numbers and translate them into something we can use on the job? The easiest way to utilize these numbers and information is to have your workers report how many units or feet of material they installed each day. They can write it on their timecard, or on the sign-in/out sheet, on a piece of paper they give to the superintendent, or on a production report they fill out each day – there are plenty of ways to collect this information. Once you have the installed quantities and the labor hours for the week (easy if they’re writing the quantities on their timecards), you can calculate a worker’s actual productivity for the day/week. It should look something like this:

By comparing Tony’s timecard to the budgeted production rates, we can see that he’s right on budget for the panel he installed, but he’s a little slow installing MC cable this week. Now that we’ve identified a problem, we can take corrective action right away.

As projects get larger, it’s often easier to collect the data and perform the production report each week. Data is collected by the foremen each day and reported to the Superintendent on Fridays. He submits the data with the timecards (typically on Mondays) and then the productivity rates can be calculated in the office. A summary report can then be sent out to the Superintendent and PM and inefficient activities can be identified, addressed, and (hopefully) resolved.

The key to managing labor costs on a project is to identify the problem areas early on so they can be addressed and resolved before they have an impact on labor costs. As projects get larger, you must have tools in place to measure progress, or it becomes impossible to accurately forecast your labor costs.

We’d love to hear your thoughts on Labor Management and Productivity. Let us know which way you’re operating, how long you’ve been that way, and what’s working for you. We love success stories!

We also have a basic man-loading schedule workbook available for FREE! Click here to download.

Read these articles next:

Rewarding Construction Project Managers - Incentive

Rewarding Construction Estimators: Incentive Packages

If you're ready to start working on your business, let's talk!

Ascent Consulting’s mission is to Build Better Construction Companies.

We are committed to delivering impressive results in the areas of

profitability, performance, and growth.

Ascent's founder and president, Adam Cooper has over three decades of experience in construction business ownership, sales & marketing, project management, construction technology, company operations and leadership.

Leave a Comment

Your email address will not be published. Required fields are marked *